Industries that rely heavily on sandblasting to clean, finish, or repair parts or surfaces include automotive, industrial machinery, and aerospace. The popularity of sandblasting not only stems from its efficiency but also its versatility. It can be used on a wide variety of smooth and rough materials, making it an ideal choice for many applications.

The sandblasting equipment used for this process varies, but the basic principle is the same: a blasting agent removes material by breaking it down into smaller pieces. This article discusses the different types of equipment used for sandblasting.

Different Types Of Blasting Equipment

Sandblasting is a technique that can be used to clean and smooth surfaces. Many different types of sandblasting equipment are available, each with its advantages. The different sandblasters have different capabilities, depending on the material being blasted. Here is a list of a few common sandblasters used in the blasting process

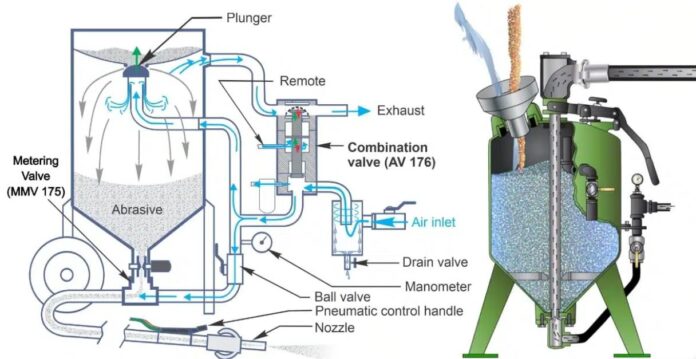

Pressure pots

Pressure pots are commonly used for sandblasting. They allow the operator to control the pressure and temperature of the blasting medium, which in turn affects the abrasion and removal of material from a target surface.

Applications for pressure pots include metalworking, manufacturing, and restoration. They can remove oxidation, rust, paint, and other contaminants from various surfaces by manipulating the pressure and temperature.

Abrasive cabinets

The cabinet contains a series of abrasive discs that can be rotated to create sanding patterns on the blasted surface. The abrasive pads cut through the paint and other debris, producing a smooth finish on the surface.

These cabinets are widely used in the sandblasting industry for various applications, such as metal removal, cleaning, and preparing surfaces for painting or coating.

Portable units

Portable units for sandblasting are used to blast away material using an abrasive blast wave. Portable sandblast units come in various shapes and sizes and can be used for multiple applications, including restoration work and refinishing.

The most common type of portable sandblast unit is the hand-held blaster. These units are small enough to be carried around easily, but they still have the power to blast away large amounts of material quickly. Hand-held blasters are also perfect for smaller projects, like restoring old furniture or cabinets.

Another type of portable sandblast unit is the tractor-mounted blaster. Tractor-mounted blasters are larger than hand-held blasters and are best suited for larger projects, like refinishing whole walls or floors.

Wet sandblasting cabinets

Wet blasting is a process of using high-pressure water to blast away material from a surface. It is most commonly used in the sandblasting industry for removing unwanted material from surfaces. Wet blasting is also used to clean and clear surfaces before painting or other types of construction.

Dry sandblasting cabinets

Dry sandblasting is a process used to remove coatings and other materials from a surface. First, the material is blasted with sand that has been finely ground. The sand abrades the material, removing it without damaging the underlying surface. Dry sandblasting removes paint, lacquer, polyurethanes, and other coatings from hard surfaces.

Wrapping Up

It is important to buy the right equipment for your industry and to do so, and it is essential to understand your industry’s specific needs. By understanding your industry’s particular needs, you can ensure that you are buying the most appropriate equipment for your business.

It is important to buy equipment of high quality and from a reputable organization to ensure the safety of those working with it. Make sure to research the specific needs of your business beforehand so that you can make an informed decision.