In the world of manufacturing, precision engineering is the key to creating products of exceptional quality.

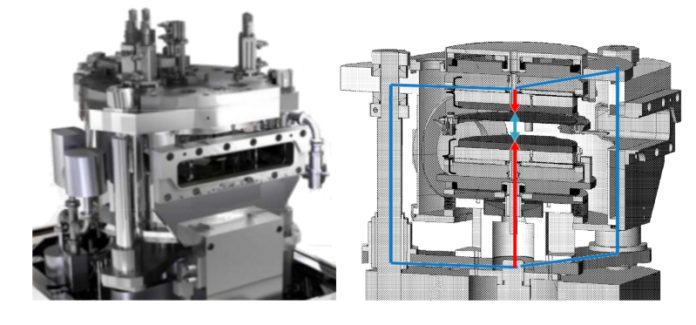

Injection molding is a core technique employed in precision engineering. This manufacturing process is renowned for its ability to produce parts with complex geometries in high volumes while maintaining strict dimensional tolerances. An injection molding manufacturer leverages cutting-edge machinery and technical expertise to ensure the production of robust and precise parts. This method is integral in various industries, including automotive, medical, and consumer electronics, where product quality and consistency are paramount.

From aerospace components to medical devices, precision engineering ensures that every detail is meticulously crafted to meet the highest standards. In this blog post, we will delve into the art of precision engineering and explore the techniques and skills required to master craftsmanship for superior quality.

1. Understanding Tolerance Levels

One of the fundamental aspects of precision engineering is understanding tolerance levels. Tolerances define the permissible limits of variation in a dimension or characteristic of a part. Precision engineers work with precise measurements and ensure that every component meets the specified tolerance range. This attention to detail ensures that parts fit together seamlessly and function flawlessly.

2. Advanced Machining Techniques

Precision engineering relies on advanced machining techniques to achieve accuracy and precision. CNC (Computer Numerical Control) machines play a crucial role in precision engineering, allowing for intricate and complex designs to be manufactured with utmost precision. Other techniques such as EDM (Electrical Discharge Machining) and laser cutting also contribute to the precision engineering process.

3. Metrology and Measurement

Accurate measurement is at the heart of precision engineering. Metrology, the science of measurement, involves using precise instruments and techniques to measure dimensions and characteristics of components. From calipers and micrometers to coordinate measuring machines (CMMs) and optical inspection systems, precision engineers utilize a range of tools to ensure accurate and reliable measurements.

4. Material Selection and Analysis

Precision engineering requires careful selection of materials based on their properties and suitability for the intended application. Engineers must consider factors such as strength, durability, corrosion resistance, and thermal stability when choosing materials. Additionally, material analysis techniques such as spectroscopy and microscopy help ensure the quality and integrity of the chosen materials.

5. Quality Control and Testing

Superior quality is a hallmark of precision engineering, and rigorous quality control measures are essential to achieve it. Precision engineers employ various testing methods, including non-destructive testing (NDT), to identify any defects or deviations from specifications. This ensures that only products meeting the highest quality standards are delivered to customers.

6. Continuous Improvement and Innovation

Precision engineering is a field that continually evolves with advancements in technology and manufacturing processes. Engineers must embrace a culture of continuous improvement and innovation to stay ahead. By staying updated with the latest techniques, tools, and materials, precision engineers can push the boundaries of craftsmanship and deliver even higher levels of quality.

7. Attention to Detail and Patience

Crafting precision-engineered components requires unwavering attention to detail and immense patience. Every step of the manufacturing process must be executed with precision, and even the smallest deviation can affect the overall quality. Precision engineers possess a meticulous mindset and take pride in their ability to master the intricacies of their craft.

8. Collaboration and Communication

Precision engineering often involves multidisciplinary collaboration. Engineers work closely with designers, material scientists, and quality control teams to ensure a holistic approach to product development. Effective communication and collaboration between teams are crucial in achieving the desired level of precision and quality.

Conclusion

Precision engineering is a blend of art and science, where craftsmanship and technical expertise converge to create exceptional products. Through understanding tolerance levels, utilizing advanced machining techniques, employing accurate metrology and measurement, selecting suitable materials, implementing rigorous quality control, embracing continuous improvement, and displaying unwavering attention to detail, precision engineers master their craft and produce superior quality components.

The pursuit of perfection drives precision engineering forward, ensuring that the products we rely on meet the highest standards of excellence.